|

| S-100 System as seen on 10/7/2016 |

|

|

|

Project Status:

Back-plane complete.

8080 CPU complete.

Front panel complete.

Power supply

Complete.

Firmware and BIOS written to EPROM.

Bootable 1GB SD card with CP/M 2.2 and other software tools.

First power on and boot to CP/M on 9/24/2016.

Enclosure

Not started

|

|

My original Netronics Explorer 85

In the early days of the micocomputer, computers based around the S-100 bus were the first home computers people used even before Apple or IBM-PC computers existed.

These largely forgotten computers, have now experienced new revival of interest by retro computer hobbyists. In the 70's and 80's there were as many as 20 major and many minor manufactures of these computers. Many of these systems were supplied as "kits".

The common denominator of all these systems was their being designed around a board with an edge connector consisting of 100 connections. Multiple boards could be plugged into such a "S-100 bus". The original S-100 bus was designed initially to support 8 bit CPU's. Over time it evolved into a bus to support 16 bit CPU's and finally was approved by the IEEE as the IEEE-696 bus.

While in 1975 the Altair was considered the cutting edge, by today’s standard, the Altair was limited. The 8080 microprocessor ran at a clock speed of only 2MHz. The unit shipped with only 256 bytes of RAM but was expandable to 64K bytes. Storage was punched paper tape, cassette tape or as show here 8 inch floppy drive. When first released, programming and data input/output on the Altair was via the many switches and LEDs on the front panel.

The MITS Altair 8800 is considered by many to be the first “personal computer.” The Altair was designed by Ed Roberts, the owner and president of Micro Instrumentation Telemetry Systems (MITS), in 1974 and sold as a kit for the cost of $439. The core of the Altair was the use of the Intel 8080 microprocessor. The 8080 normally sold for over $300 each but Roberts was able to acquire cosmetically blemished versions of 8080 for $75 each in large volumes. These versions worked just as well as the more expensive ones, allowing the Altair 8800 to be released more affordable price. At first the popularity of the Altair was limited. This all changed with the release of the January 1975 issue of Popular Electronics magazine. Within a month orders for the Altair jump dramatically. MITS couldn’t keep up with demand and some buyers camped in the company’s car park waiting for their machines.

While in 1975 the Altair was considered the cutting edge, by today’s standard, the Altair was limited. The 8080 microprocessor ran at a clock speed of only 2MHz. The unit shipped with only 256 bytes of RAM but was expandable to 64K bytes. Storage was punched paper tape, cassette tape or as show here 8 inch floppy drive. When first released, programming and data input/output on the Altair was via the many switches and LEDs on the front panel.

The MITS Altair 8800 is considered by many to be the first “personal computer.” The Altair was designed by Ed Roberts, the owner and president of Micro Instrumentation Telemetry Systems (MITS), in 1974 and sold as a kit for the cost of $439. The core of the Altair was the use of the Intel 8080 microprocessor. The 8080 normally sold for over $300 each but Roberts was able to acquire cosmetically blemished versions of 8080 for $75 each in large volumes. These versions worked just as well as the more expensive ones, allowing the Altair 8800 to be released more affordable price. At first the popularity of the Altair was limited. This all changed with the release of the January 1975 issue of Popular Electronics magazine. Within a month orders for the Altair jump dramatically. MITS couldn’t keep up with demand and some buyers camped in the company’s car park waiting for their machines.

While in 1975 the Altair was considered the cutting edge, by today’s standard, the Altair was limited. The 8080 microprocessor ran at a clock speed of only 2MHz. The unit shipped with only 256 bytes of RAM but was expandable to 64K bytes. Storage was punched paper tape, cassette tape or as show here 8 inch floppy drive. When first released, programming and data input/output on the Altair was via the many switches and LEDs on the front panel

|

How my S-100 project began

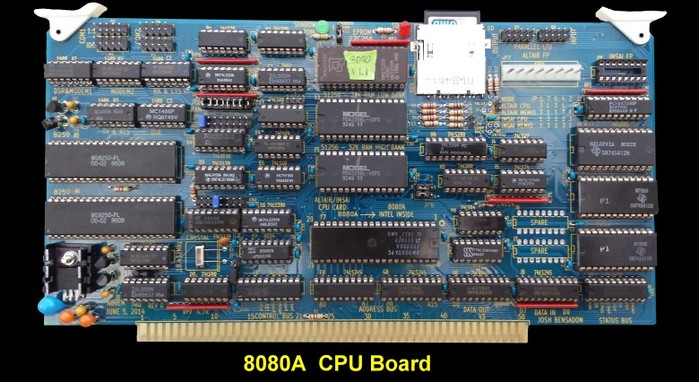

Josh's S-100 8080 CPU board

My S-100 based build all started when I received and email from Josh out of Canada. Like myself, Josh also builds and restores computers based around the COSMAC CPD1802. It was through this common ground that he reached out to me. He wished to know if I would be interested in a new board that he already designed and manufactured. This new board used the original Intel 8080 as it microprocessor.

"Dave, would I be interested in one?"

" Absolutely YES I would defiantly like one."

I already had the idea to build some form of Retro S-100 based computer system. Some 35 plus years ago, I had already built several S-100 systems.

My original system was the Netronics Explorer 85 with an Intel 8085 microprocessor and two S-100 slots on the main board. This S-100 system was the system I designed and build my first S-100 floppy disk controller based on the then new Western Digital 1771 floppy disk controller chip. I even had to wrote my first primitive disk operating system I call simply Dave's DOS.

My next S-100 system used a conventional S-100 back-plane. At its high point I had a Jade Electronics Z80 CPU board with a Z80B microprocessor, three 16K static RAM cards for a total of 48K of RAM, a dual high speed serial board, my final version quad floppy disk controller card that supported two 8" and two 5.25" floppy disks, and a very heavy analog power supply that provided 8 volts DC at 20 amps, 16 volts DC at 5 amps and -16 volts DC at 5 amps.

User interface was provided using a Heathkit H9 terminal and a H14 dot-matrix printer.

There was also a 1200/2400 baud Cat MODEM I used to remotely connect. During my days in Collage, I would call-in to my S-100 system to do my home work and write programs for the computer science labs which was using a Intel SDK85 trainer which was conveniently based around the Intel 8085 microprocessor.

In the end, Josh and I did an exchange deal where I received one of his new S-100 8080 CPU boards for a set of my Retro Elf Plus boards and their supporting programmable logic arrays.

|

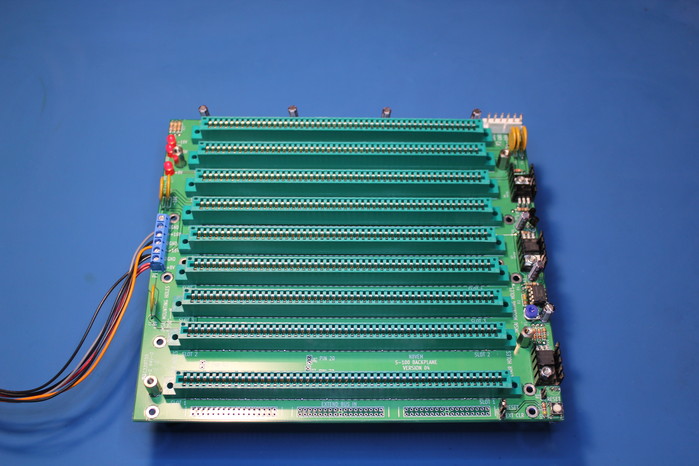

The heart of my system, the S-100 Back-plane

My S-100 Back-plane

The heart of any S-100 system is the S-100 back-plane. It's the type of 100-pin connectors used and pin-out of each pin in these connectors, that defines a system as a "S-100" system. With help from Josh, I picked a nice nine connector S-100 back-plane supplied from N8VEM who like myself, must be an amateur Radio Operator. One feature I liked, is the support of both the original Altair 8800 and the IMSAI mounting holes and board spacing patterns.

Issues found and modification made during the build of the S-100 back-plane

There are three monitoring LEDs for the +8 volt DC, +16 volt DC and -16 volt DC power supplies. The resisters used at R15, R16, R17 where 4.7K ohms, 20K ohms and 20K ohms. The red LEDs used where found to be very dim in operation. A quick calculation found that the +8 volt LED was only getting about 1mA of current while the +/-16 volt LEDs only had 0.7mA of current. The data sheet for the LEDs indicated the best operational current for normal rated brightness is between 4-10mA. Resistor R15 was changed to 1K ohms to yielding a 6mA LED drive current. The two resistors at R16 and R17 where changed to 2K ohms yielding a 7mA LED drive current. With these new values, each LED is nice and bright.

There are several errors within the parts list I found at the website supporting the back-plane. In the active back-plane design, several SIP resistor packs are used as terminators for each S-100 bus signal. The sip resister type selected consisted of a 270 ohm, 10-pin SIP package. Unfortunately the physical board only supports a 9-pin SIP package. I made my discovery of this error when I tried to place the 10-pin SIPs in to their respective locations.

On the next parts order to Digikey, I identified and ordered the correct 9-pin replacements. While I was as it, I also ordered MillMax SIP sockets to solder in to the the active bus resistor pack locations. I then placed the new 9-pin sips in to these SIP sockets. This addition allows me to remove the SIP resistors turning the S-100 back-plane from active one to a passive one when needed.

There was also a wrong vendor part number given for several resistors. The values listed in the description was correct but the vendor part number was wrong.

I updated the power supply connector at P1. Personally I like to used screw terminals for connecting the power supply wires. The back-plane board uses a 0.2 inch spacing for the pins on P1. This spacing is just right to support three horizontal, 2-position wire to board terminal blocks. I selected On-Shore Technology, Inc. OSTTC022162 (Digikey part number ED2609-ND). These 2-position wire to board terminal blocks can be end stacked together to create a signal 6-position wire to board terminal block.

The heat-sink at IC1 has a interference issue with C1 and also one of the mounting holes by IC1. Even without the heat-sink the voltage regulator interferes with C1 when screwed to the PC board. The listed heat-sink also hang over the edge of the PC board. I changed the Aavid Thermalloy heat-sinks listed from a 507302B00000G (Digikey part number HS115-ND) to a narrower 577202B00000G (Digikey part number HS107-ND).

The 39uF capacitor at C1 was moved to the bottom of the PC board and the leads where bent over so that the capacitor would lay flat under the reset button at SW1. Additionally a small bead of thermal glue was used to help attach C1 in place on the underside of the board. A smaller headed screw was select to fix the mounting hole issue.

Like the heat-sink at IC1, the two heat-sinks at Q3 and Q4 also hang over the edge of the board. In addition, a possible short to other active foil traces that run under the heat-sinks could exist. While there is solder-mask covering the traces that run under the heat-sinks, I am personally uncomfortable depending on the solder-mask to act as an insulator between traces and heat-sink. In my implementation, both of the Aavid Thermalloy heat-sinks 507302B00000G (Digikey part number HS115-ND) were changed to Aavid Thermalloy heat-sinks 577202B00000G (Digikey part number HS107-ND). Two Aavid Thermalloy 56-77-11G (Digikey part number 56-77-11G-ND) 18.92mm x 13.84mm rectangle thermal pads where also placed under each of the two heat-sinks to increase the electrical isolation between heat sink and board traces.

|

The S-100 back plane requires the three DC voltages of +8, +16 and -16 volts. The +8 volt DC supply is used mainly to drive the digital logic in the system. The +/-16 volt supplies support the RS-232 interface, any analog devices and the 8080 microprocessor which unlike most future microprocessors, required regulated +12, +5 and -5 volts to operate. At first I looked at creating a large and heavy analog power supply with a big transformer like the ones found in systems like the IMSAI 8080 or the Altair 8800. While this world fit the retro feel better, I finally opted to use modern AC to DC switching converters for the first round on my S-100 computer system. Maybe in a few months I will revisit the power supply needs and opt to design a retro stile analog boat anchor type power supply. I ended up using two open frame type AC to DC converters. While I could not locate units that supported the exact voltages needed, both of the selected units where adjustable to the required +8 and +/-16 volts needed. Here is the parts list and schematic for the power supply section I'm currently using:

| QTY |

Description

|

Vendor |

Vendor # |

Manufacturer |

MFG # |

| 1 |

Open frame AC DC converter, 1-output 9VDC @2.8A, 85~264VAC input |

Digikey |

1470-1192-ND |

XP Power |

ECL25US09-T |

| 1 |

Open frame AC DC converter, 2-outputs +/-15VDC @1A, 85~264VAC input |

Digikey |

1470-1206-ND |

XP Power |

ECL30UD02-T |

| 2 |

3-position rectangular housing |

Digikey |

455-2219-ND |

JST Sales |

XHP-3 |

| 1 |

5-position rectangular housing |

Digikey |

455-2268-ND |

JST Sales |

XHP-5 |

| 1 |

6-position rectangular housing |

Digikey |

445-2218-ND |

JST Sales |

XHP-6 |

| 11 |

Contact crimp socket, 22-28AWG, tin |

Digikey |

455-1135-1-ND |

JST Sales |

SXH-001T-P0.6 |

|

|

| S-100 system power supply |

|

|

Pictured above is my completed S-100 8080 CPU board. As covered at the beginning, the CPU being used in the S-100 project is one designed by Josh out of Canada. On October 2012 he visited the PC Museum of Ontario ( www.pcmuseum.ca) where he found that their IMSAI 8080 was no longer functional. Since his hobby is rebuilding and restoring retro computer systems, he decided to work on restoring their unit to a run-able condition. As Josh enplanes in his manual for the 8080 board, There where several challenges that needed to be considered. Their system did not included any from of disk drive and the boards already installed seamed to be mismatched. While he was driving home, Josh began to think about building a form of CPU board that would be a all-in-one card. Include features like on-board storage to replace the missing disk drives. The resulting board also needed to work with the least amount of onsite support. Several release later, the resulting S-100 8080 CPU board is the one I will use in my S-100 system. Building the S-100 8080 CPU boardI completed the assembly of the CPU board with just a few issues. One of the more interesting issues was my decision to use the National Semiconductor PC16550 UARTs I had in my current stock over the recommended WD8250 listed in the design. The popular theory states that the PC16550 is backwards compatible to the original WD8150. I quickly learned that, in this design, only the WD8250 worked. So a quick order WD8250s from a supplier on eBay and a few days later they arrived. Placed the Wd8250s in to he CPU board in place of the PC16550s and now serial communications is fully restored. In October 2016, Josh sent me an email letting me know he found what was the issue that prevented the PC16550 UART from working. It turned out that pin 25 (Address Strobe or -ADS) needed to be grounded. I added the suggested jumper between pin 25 and pin 22 on each of the two UARTs and exchanged the WD8250s with two PC16550s. This indeed fixed the issue and my system now works with both the original WD8250 and the newer PC16550. While it is nice to have the option to use either chip, since I bought the WD8250s already, I ended up using them for this system. Another more successful change I did substituted the 7805 +5VDC analog voltage regulator with a CUI Inc's OKI-78SR-5 (Digikey part number 811-2196-5-ND) a +5VDC, DC-to-DC, 7.5W converter. I have used these DC-to-DC converters in several of my own designs and have them in my stock. Using this part removed the need to the added heat sink and would support loads of up to 2 amps with an input voltage as high as 36VDC. In the documentation for the S-100 8080 CPU board, Josh also provided a DC-to-DC converter option. The unit he pick would have work wonderfully. I just had many of the OKI-78SR-5s in my stock already. tttIn October 2012, I visited the PC Museum of Ontario (www.pcmuseum.ca)

and decided to get their IMSAI 8080 computer running. They did not have a disk

drive and the installed boards looked mismatched. On the drive home I thought

of building an all-in-one CPU board that would work with the least amount of onsite

work. By my next visit in April 2013, I had built the first replacement board

on one of Andrew Lynch’s S-100 Unbuffered Prototyping boards1

. This first

board had 64K of SRAM and a PIC chip to provide a simulated Disk Drive,

Console I/O and Boot ROM. An 8Meg Flash memory chip was connected to the

PIC’s SPI to host 4 possible disks. The PIC’s USART provided the Console I/O.

Upon reset, the PIC would “spoon feed” the 8080A. It supplied the 8080A CPU

with instructions that would save a boot strap in RAM. Then a jump to that

location would release this “spoon feed” mode and allow the 8080A execute this

boot strap program. With the help of Rich Cini’s paper on boot strapping CP/M,

I was able to write a copy for this system. On site, I only needed to repair the

front panel board and then install this all-in-one CPU board to get a working

IMSAI system. After this success, I presented the idea of this board to the

N8VEM group and many of your ideas were put on paper and I began working

on this version of the board. Many of those ideas are listed in the next chapter

that covers features, but one idea that is not listed there was the removal of the

PIC chip.

In October 2012, I visited the PC Museum of Ontario (www.pcmuseum.ca)

and decided to get their IMSAI 8080 computer running. They did not have a disk

drive and the installed boards looked mismatched. On the drive home I thought

of building an all-in-one CPU board that would work with the least amount of onsite

work. By my next visit in April 2013, I had built the first replacement board

on one of Andrew Lynch’s S-100 Unbuffered Prototyping boards1

. This first

board had 64K of SRAM and a PIC chip to provide a simulated Disk Drive,

Console I/O and Boot ROM. An 8Meg Flash memory chip was connected to the

PIC’s SPI to host 4 possible disks. The PIC’s USART provided the Console I/O.

Upon reset, the PIC would “spoon feed” the 8080A. It supplied the 8080A CPU

with instructions that would save a boot strap in RAM. Then a jump to that

location would release this “spoon feed” mode and allow the 8080A execute this

boot strap program. With the help of Rich Cini’s paper on boot strapping CP/M,

I was able to write a copy for this system. On site, I only needed to repair the

front panel board and then install this all-in-one CPU board to get a working

IMSAI system. After this success, I presented the idea of this board to the

N8VEM group and many of your ideas were put on paper and I began working

on this version of the board. Many of those ideas are listed in the next chapter

that covers features, but one idea that is not listed there was the removal of the

PIC chip. The final issue that came up once the board was completed, was the discovery of a software limit in the V2.4 AIRBL ROM firmware. It tuns out that this version only supported SD cards with a pure FAT-16 format and hence had to be less than 2GB in size. I tried to use SC cards that supported greater than 2GB of data by building 1 and 2 GB partitions and format them with FAT-16. All these attempts failed.

|

From the very beginning, one of goals was the use of a full featured front panel for my S-100 system. The front panel selected is a modern reproduction based on the front panel found on the front of the original IMSAI 8080. This newer version of front panel board was designed and produced by Don Caprio. Designed as a shoe-in replacement for the IMSAI front panel, it featured a set of switches that closely matched the original functions found on the IMSAI version it was modeled on. The front panel allows the examine memory, depositing bytes in to RAM, halting the CPU and single stepping through code while viewing the various status and control lines on the S100 Bus. I ended up ordering a bare PCB, all the color correct paddle switches, a supporting toggle switch mounting kit with hardware and a the hard-to-find P8212 integrated circuit. There is a total of 44 LED providing system information for the 16-bit address and the 8-bit data buses. There are 12 status indicators for MEMR, INP, M1, OUT, HLTA, STACK,W0, INTA, INTERRUPTS ENABLE, RUN, WAIT and HOLD. Finally there is the eight bit data output LEDs that software can use to indicate different statuses or operating modes. Like the original IMSAI front panel, the eight bit data output port LEDs are inverted. If the LED is on then that bit is in a low state. Likewise if the LED is off then that bit is in a high state. This strange inverted behavior is contributed to the drive current limits of the 8212 integrated circuit used to drive the eight LEDs on this output port. The 8212 can sink (pull to ground) about 12mA while it can only source (pull to +5V) about 0.5mA. Each LED and accompanying current limiting resistor are setup to draw about 12mA, so only the 8212's sinking capabilities can be used to drive the LEDs. This results in a low on any output bit placing that bit in to sink mode allowing the LED to conduct and hence light. Front panel control and data input is provided through a total of 21 paddle toggle switches. Five paddle switches control the system's operational functions. Each of the five switches have a toggle up or toggle down position with an automatic spring returns to the middle position when released. This gives each of the five control switches two operation functions. Logically related functions are grouped on each toggle. For example on one switch the EXAMINE function uses a toggle up operation while the EXAMINE NEXT function is activated with a toggle down. Likewise the DEPOSIT/ DEPOSIT NEXT and RUN/STOP are also grouped. The two toggles for RESET and SINGLE STEP will produce the same results when activated in ether the up or down positions. 16 toggle are used to load a new address in to the CPU's program counter. The upper eight toggles are also tasked to deposit data on to the the data bus at the current CPU program counter location. Building the S-100 front panel boardThe board received was the current revision F version of the board. Unfortunately when I went to order the remaining parts to complete the board, all the supporting on-line documentation was for older versions of the board. For example, the bill-of-materials was for the original revision A board while the two schematics seemed to cover revisions D and E. So before I was conferrable ordering any parts, a corrected bill-of-materials supporting the revision F board needed to be created. The following is the version of bill-of-materials used during my build.

| Location |

QTY |

Description |

Vendor |

Vendor # |

Manufacturer |

Mfg #

|

C1,C2,C5,C6,

C7,C8,C11,

C12,C13,C14,

C15,C16,C18,

C19,C20,C21,

C22,C23,C24,

C25,C26,C27,

C28,C29,C30,

C31,C32,C33,

C34,C35 |

30 |

Capacitor, Ceramic, 0.1uF, 100V, 20%, Radial |

Digikey |

399-4388-ND |

Kemet |

C330C104M1U5TA |

| C4 |

1 |

Capacitor, Ceramic, 0.01uF, 50V, Z5U, Radial |

Digikey |

399-4150-ND |

Kemet |

C315C103M5U5TA |

| C3 |

1 |

Capacitor, Ceramic, 0.001uF, 50V, Z5U, Radial |

Digikey |

399-9770-ND |

Kemet |

C320C102M5R5TA |

| C9 |

1 |

Capacitor, Dipped Tantalum, 0.1uF, 35V, 10%, Radial |

Digikey |

399-3526-ND |

Kemet |

T350A104K035AT |

| C10 |

1 |

Capacitor, Dipped Tantalum, 0.33uF, 35V, 10%, Radial |

Digikey |

399-3613-ND |

Kemet |

T356A334K035AT |

| CR1 |

1 |

Diode, 1N4148 |

Digikey |

1N4148FS-ND |

Fairchild |

1N4148 |

D0,D1,D2,D3,

D4,D5,D6,D7,

D8,D9,D10,

D11,D12,D13,

D14,D15,D16,

D17,D18,D19,

D20,D21,D22,

D23,D26,LD0,

LD1,LD2,LD3,

LD4,LD5,LD6,

LD7,LA15 |

34 |

LED, 5mm, Red |

Digikey |

754-1266-ND |

Kingbright |

WP7113LID |

| D24,D27 |

2 |

LED, 5mm, Yellow |

Digikey |

754-1268-ND |

Kingbright |

WP7113LYD |

| D25 |

1 |

LED, 5mm, Green |

Digikey |

754-1265-ND |

Kingbright |

WP7113LGD |

| R1 |

1 |

Resistor, 270K Ohm, 1/4W, 5% |

Digikey |

270KQBK-ND |

Yageo |

CFR-25JB-52-270K |

| R2 |

1 |

Resistor, 200 Ohm, 1/4W, 5% |

Digikey |

200QBK-ND |

Yageo |

CFR-25JB-52-200R |

RR1,RR2,RR3,

RR5,RR6 |

5 |

Resistor, 220 Ohm, 2%, 10-pin SIP |

Digikey |

4310R-1-221LF-ND |

Bourns |

4310R-101-221LF |

| RR4 |

1 |

Resistor, 1K Ohm, 2%, 10-pin SIP |

Digikey |

4310R-1-102LF-ND |

Bourns |

4310R-101-102LF |

| RR7 |

1 |

Resistor, 4.7K Ohm, 10-pin SIP |

Digikey |

4610X-1-472LF-ND |

Bourns |

4610X-101-472LF |

SA0,SA1,SA2,

SA3,SA8,SA9,

SA10,SA11 |

8 |

Switch, SPDT, Mini-Paddle, Red |

Retro Computer Products |

M2012TNW03-EC |

NKK |

M2012TNW03-EC |

SA4,SA5,SA6,

SA7,SA12,SA13,

SA14,SA15 |

8 |

Switch, SPDT, Mini-Paddle, Blue |

Retro Computer Products |

M2012TNW03-EG |

NKK |

M2012TNW03-EG |

| SW2,SW4,SW4 |

3 |

Switch, SPDT, Mini-Paddle, spring return, center off, Blue |

Retro Computer Products |

M2018TNW03-EG |

NKK |

M2018TNW03-EG |

| SW3,SW5 |

2 |

Switch, SPDT, Mini-Paddle, spring return, center off, Red |

Retro Computer Products |

M2018TNW03-EC |

NKK |

M2018TNW03-EC |

U1,U3,U4,

U6,U7 |

5 |

IC, 74LS05 |

Digikey |

296-1631-5-ND |

TI |

SN74LS05N |

| U5 |

1 |

IC, 8212 |

Retro Computer Products |

i8212 |

Intel |

P8212 |

| U8,U10,U15 |

3 |

IC, 74LS04 |

Digikey |

296-1629-5-ND |

TI |

SN74LS04N |

| U9,21 |

2 |

IC, 74LS30 |

Digikey |

296-3693-5-ND |

TI |

SN74LS30N |

| U11,U12 |

2 |

IC, 74LS10 |

Digikey |

296-1634-5-ND |

TI |

SN710N4LS |

| U13,U16 |

2 |

IC, 7402 |

Digikey |

296-33594-5-ND |

TI |

SN7402N |

| U14,U25 |

2 |

IC, 7400 |

Digikey |

296-14641-5-ND |

TI |

SN7400N |

| U15.5 |

1 |

IC, 7427 |

Jameco |

50139 |

TI |

SN7427N |

| U17,U20,U23 |

3 |

IC, 74LS123 |

Digikey |

296-1636-5-ND |

TI |

SN74LS123N |

| U18,U19,U22 |

3 |

IC, 74LS107 |

Digikey |

296-33952-5-ND |

TI |

SN74LS107N |

| U24 |

1 |

IC, 74LS367 |

Digikey |

296-3701-5-ND |

TI |

SN74LS367AN |

| U26 |

1 |

IC, 7805 |

Digikey |

MC7805CT-BPMS-ND |

Micro Commercial |

MC7805CT-BP |

U1,U3,U4,U6,

U7,U8,U9,U10,

U11,U12,U13,

U14,U15,U15.5,

U16,U18,U19,

U21,U22,U25 |

20 |

Socket, 14-pin DIP |

Digikey |

AE10012-ND |

Assmann WSW Components |

AR 14-HZL-TT |

| U5 |

1 |

Socket, 24-pin DIP |

Digikey |

AE10016-ND |

Assmann WSW Components |

AR 24-HZL-TT |

U17,U20,U23,

U24,P2 |

5 |

Socket, 16-pin DIP |

DIgikey |

AE10013-ND |

Assmann WSW Components |

AR 16-HZL-TT |

| NA |

1 |

PC board, S-100 Front Panel |

Retro Computer Products |

FPmini-E |

Retro Computer Products |

FPmini-E |

| NA |

1 |

Kit, toggle switch support bracket with hardware |

Retro Computer Products |

FPMini-bracket-fr4 |

Retro Computer Products |

FPMini-bracket-fr4 |

| U26 |

1 |

Heatsink, TO-220, 2.5W, Low profile |

Digikey |

HS115-ND |

Aavid |

507302B00000G |

| U26 |

1 |

Machine screw, PAN head Phillips, M3 |

Digikey |

335-1149-ND |

APM Hexseal |

RM3X8MM2701 |

| U26 |

1 |

Hex nut, 0.217 inch, M3 |

Digikey |

H762-ND |

B&F Fastener |

MHNZ 003 |

JP1,JP2,JP3,JP4,

JP5,JP6 |

6 |

2-pin header 0.1 Gold |

Digikey |

3M9447-ND |

3M |

961102-6404-AR |

JP1,JP2,JP3,JP4,

JP5,JP6 |

6 |

2-pin shunt connector |

Digikey |

952-2165-ND |

Harwin |

M7567-46 |

| P2 |

2 |

Connector DIP 16-pin, Gold IDC |

Digikey |

CDP16G-NG |

CW Industries |

CWR-130-16-0000 |

| P2 |

1 |

Flat ribbon cable 16 conductor |

Digikey |

MC16M-5-ND |

3M |

3302/16 300SF |

Once all the parts arrived, the building of the PCB went without any issues. The fully populated finished board was plugged in to the S-100 back-plane and the 16-pin ribbon cable was connected between the front panel and the CPU boards. Powering up was uneventful and all front panel functions worked the first time.

|

|

|