The Quest Electronic's COSMAC Elf

|

|

|

|

The date was August 1977 and in this issue of Popular Electronics, I found this ad form Quest Electronics. In the ad there was listed "Cosmac 'Elf' Kit." The board for just $14.95.

I had to have this board!

It would take me another several months to save enough money to order the "Cosmac Elf kit." Little did I realize, that this simple order, for my first computer, would change my life forever!

The hunt for my first computer really started over a year earlier. On January 1975, Popular Electronics released the Altair 8800. While my first dream was to buy and build the Altair from Mits, at 15 years of age, I just did not have the funds needed to by the $621 kit.

On August 1975, Popular Electronics released the article titled "The COSMAC 'Elf' - A microcomputer trainer that's powerful, expandable and cost as little as $80".

I started to save my money and a year later the Quest Electronics ad put me within a few months to affording the parts needed to build the Elf. I bought the board and parts in November 1977.

By the end of November, my Quest COSMAC Elf was put together and I was happily writing my first 1802 assembly programs based on the Popular Electronics series.

But time and technology move on...

Over the past 35 plus years my original Elf was replaced by the more expandable Quest Electronics Super Elf and then other more powerful systems. At some point the original Elf got dumped into a box and bounce from place to place and finally ended up in my storage locker where it remained lost and forgotten.

Then one day while I was cleaning "junk" out of my several storage locations, I ran across my very first original Elf. Time was hard on the Elf, stained by water, some type of oil and covered in dirt and dust. I do not know why but the retro computing phase I'm going though complied me to take the old Elf back to my work shop. My goal is to rebuild the unit to a fully functional state and place it in a nice display case for others old timer geeks like myself to admire.

|

|

Phase I - Removing all the parts from the PC board and cleaning

Front with parts removed

The first challenge was to remove all the parts from the PC board. At some point some form of motor oil had be spilled on to the board. This allowed all the dust and dirt to become some form of yuck coasting on the parts and the board. So the best option to restoring the Elf to its former clean and running state required all the part to be removed.

Parts like resistors, capacitors, diodes, IC sockets and switches where still readily available from parts suppliers. These parts where carefully cut off the board and discarded for later replacement.

The no longer manufactured parts like the original CDP1802 processor, the two 2101 RAMs, the 82S123 PROM and the two TIL311 HEX displays where very carefully removed, carefully cleaned, placed on anti-static foam and stored in a anti static storage box. Like a antique diamond ring, these parts where locked away for safety.

The unsoldering of parts and removing the excess solder from all the holes was done slowly, with much thought and care. Had to be careful not to damage the foil traces, component pads or platting in the holes. In the end one oops did occurred. The center lead of the RUN toggle switch (S13) was already damaged and the foil on the board was cracked and loose. When the switch was unsoldered and removed, the plating in the hole came free with the removed switch. In addition about half inch of foil trace on the component side of the board close to the removed the switch also pulled up. You can see the damage on the bare board picture and the patch on the high resolution picture of the restored board.

Now that all the part had been removed, it was time to clean off the 35+ years of old dirt. I found that several passes with 91% isopropyl alcohol and a paper towels cleaned off most of the unwanted goo and did not damage the board's foil traces. The final remaining unwanted goo was removed using a can of solder flux remover and one more pass with the isopropyle.

I then took high resolution digital picture of both sides (the same pictures seen on this page) of the board. I used these pictures to inspect the overall board for any problem areas like micro foil or pad damage.

|

|

| Back with parts removed |

|

|

PHASE II - Documentation and replacement parts ordering

I had lost my original schematic for the revision 2.1 board I build back in 1977. I ended up having to reverse engineering the above version from the original Quest Electronics printed circuit board dated 9-12-1977.

After I had completed the project, I ran in to another 1802 collector who also had an original Quest Elf. He generously provided me with a scanned copy of the original Quest schematic shown bellow.

But there is something interesting missing. On the board there are part locations for another voltage regulator and supporting parts. I had never installed these parts on my original unit. I tried to "best guess" what was intended to go there in my schematic. Once I received the original Quest schematic I was surprised to find that it to did not have any indications as to what parts go in to these extra holes.

I am not sure if my guess is correct at all. Again I still have not added these parts to my unit. I am still working on finding what these extra parts are and one I know I will update this web page and add them to my unit.

The final documentation step was the creation of a parts list for the Elf. I used both versions of the schematics and a on-line parts list I located to generate the following parts list.

|

| Location |

QTY |

Description |

Manufacture |

MFG # |

| AC, +BAT, SPKR |

3 |

2 place screw type PC terminal block |

On Shore Technology Inc. |

OSTTC022162 |

| C1, C2 |

2 |

Capacitor ceramic 30pF 50V 5% 0.2 pitch radial |

Kemet |

C317C300J5G5TA |

| C3, C7, C8 |

3 |

Capacitor ceramic 0.1uF 100V 20% 0.2 pitch radial |

Kemet |

C330C104M1U5TA |

| C4 |

1 |

Capacitor 1000uF aluminum 20% 25WVDC axial |

Nichicon |

TVX1E102MCD |

| C5 |

1 |

Capacitor 10uF aluminum 20% 25WVDC axial |

Nichicon |

TVX1E100MAD |

| C6 |

1 |

Capacitor 100uF aluminum 20% 25WVDC axial |

Nichicon |

TVX1E101MAD |

| C9, C10, C11, C12 |

4 |

Capacitor ceramic 0.1uF 50V 10% axial |

Cornell Dubilier Electronics (CDE) |

P20R104K5-F |

| CR1, CR2, CR3, CR4, CR5, CR6 |

6 |

Diode 1N4148 100V 200mA DO35 |

Fairchild Semiconductor |

1N4148 |

| CR7, CR8, CR9, CR10, CR11 |

5 |

Diode 1N4001 50V 1A DO41 |

Fairchild Semiconductor |

1N4001 |

| L1 |

1 |

LED Red diffuse 5mm round |

Kingbright |

WP7113LID |

| Q1 |

1 |

Transistor NPN 2N2222 or PN2222 |

Fairchild Semiconductor |

PN2222ABU |

| R1 |

1 |

Resistor 100 ohm 5% 1/4 Watt axial |

Yageo |

CFR-25JB-52-100R |

| R2, R4, R5, R6, R7, R8, R9, R11, R12, R13, R14, R15 |

12 |

Resistor 47K ohm 5% 1/4 Watt axial |

Yageo |

CFR-25JB-52-47K |

| R3 |

1 |

Resistor 1K ohm 5% 1/4 Watt |

Yageo |

CFR-25JB-52-1K |

| R10 |

1 |

Resistor 1M ohm 5% 1/4 Watt |

Yageo |

CFR-25JB-52-1M |

| S1, S2, S3, S5, S6, S7, S8, S9, S10, S12, S13, S14 |

12 |

Switch toggle SPDT 0.4VA 20V |

C&K Components |

7101SYCBE |

| S4 |

1 |

Switch toggle SPDT 5A 120V spring return |

C&K Components |

7108SYCQE |

| S14 |

1 |

Switch toggle SPST 2A 120V |

C&K Components |

T102SHZQE |

| SPKR |

1 |

Speaker enclosure 0.5W 8 ohm |

PUI Audio Inc. |

ASE02008MR-LW150-R |

| U1 |

1 |

CDP1802 Microprocessor 8-bit |

Reuse Vintage part

RCA |

CDP1802CE |

| U2 |

1 |

IC CD4013 dual CMAS D flip-flop |

Texas Instruments |

CD4013BE |

| U3, U5 |

2 |

MM2101 SRAM 256 x 4 |

Reuse Vintage part

NEC |

MM2101AL-4 |

| U4, U10 |

2 |

IC CD4049 hex buffer/inverter |

Texas Instruments |

CD4049UBE |

| U6 |

1 |

82S123 PROM 32 x 8 |

Reuse Vintage part

|

82S123 |

| U7, U8 |

2 |

IC CD4050 hex buffer/converter |

Texas Instruments |

CD4050BE |

| U9, U11 |

2 |

Display TIL311 with hexadecimal logic |

Reuse Vintage par

Texas Instruments |

TIL311 |

| U12 |

1 |

IC CD4011 Quad 2-input CMOS NAND gate |

Texas Instruments |

CD4011BE |

| U13 |

1 |

IC CD4023 Tri 3-input CMOS NAND gate |

Texas Instruments |

CD4023BE |

| U14, U15 |

2 |

IC CD4016 Quad bilateral CMOS switch |

Texas Instruments |

CD4016BE |

| U16 |

1 |

LM7805 Analog regulator 5VDC @ 1 A |

Micro Commercial Co |

MC7805CT-BP |

| U16 |

1 |

Heat sink |

Aavid Thermalloy |

530614B00000G |

| U16 |

1 |

Screw 4-40 x 3/8 inch |

Line stock |

N/A |

| U16 |

1 |

Nut 4-40 |

Line stock |

N/A |

| U17 |

1 |

? |

N/A |

N/A |

| U1 |

1 |

IC socket 40-pin tin |

Assmann WSW Components |

AR-40-HZL-TT |

| U2, U12, U13, U14, U15 |

5 |

IC socket 14-pin tin |

Assmann WSW Components |

AR-14-HZL-TT |

| U3, U5 |

2 |

IC socket 24-pin tin (Need to modify for 22-pin) |

Assmann WSW Components |

AR-24-HZL-TT |

| U4, U6, U7, U8, U10 |

5 |

IC socket 16-pin tin |

Assmann WSW Components |

AR-16-HZL-TT |

| X1 |

1 |

Crystal 1MHz |

Reuse vintage part |

N/A |

| |

1 |

Connector 2 x 5.5mm vertical power panel mount |

CUI Inc. |

PJ-065A |

| |

1 |

AC/DC wall mount adapter 9 volt 7 watt |

Triad Magnetics |

WSU090-0800 |

| |

1 |

PC Board |

Reuse vintage part

Quest Electronics |

N/A |

|

2 |

Polycarbonate 8 1/2 x 6 1/2 x 1/4 inch clear |

Line Stock |

N/A |

|

4 |

Spacer 6-32 x 1 inch aluminum spacers |

Line Stock |

N/A |

|

4 |

Spacer 6-32 x 1/2 inch aluminum |

Line Stock |

N/A |

|

4 |

Screws 6-32 x 1 1/2 inch Philips head stainless steel |

Line Stock |

N/A |

|

6 |

Screws 6-32 x 3/8 inch Philips head stainless steel |

Line Stock |

N/A |

|

1 |

Angle 7 3/8 x 1 x 1/8 inch aluminum |

Line Stock |

N/A |

|

4 |

Glue on rubber feet |

Line Stock |

N/A |

|

With all the documentation completed and replacement parts ordered, reassembly could start. First I installed the smaller, low profile components like resistors and diodes. Then came the new high quality IC sockets. Next came the taller capacitors and other lager components.

The last parts to be installed where the thirteen switches. Some thought was given to make sure that each switch had proper spacing and alignment. The best method to accomplish this alignment ended up with the fabrication of an alignment plate. A piece of 7 x 1 1/2 x 1/8 inch thick aluminum bar stock was pressed to to service. A trip to the CAD workstation generated the drawing for the switch locations. This drawing was printed out at one-to-one on the LASER printer and then taped to the aluminum bar stock. A quick stop at my drill press for some careful hole drilling, produced the needed alignment plate.

All the switches where then attached to the alignment plate with their supplied mounting hardware. The switches pins where then placed through the correct holes. Positioning and alignment was carefully measured and the switches where finally soldered into place.

The switches where removed form the plate and the plate was saved to be used as a template for future holes needed by the enclosure yet to come.

The resulting reassembled PC board can be seen below undergoing functional testing.

|

|

| The final assembled board being tested |

|

|

Enclosing the Finished Quest COSMAC ELF

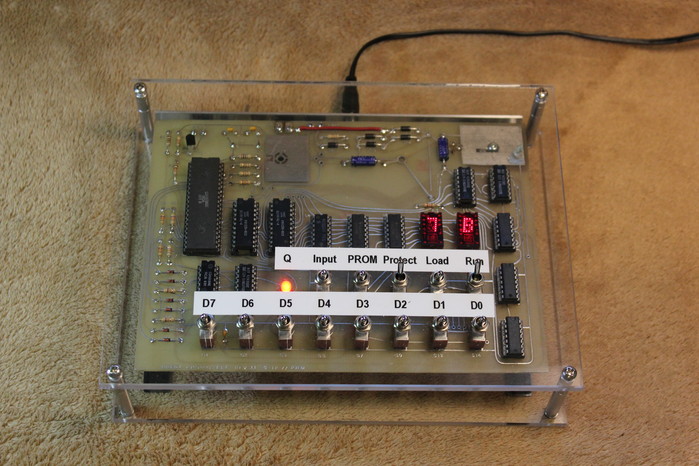

Front view of the finished Quest Elf I

Originally my plan was to place the finished Elf in to a nice wooden box with a clear polycarbonate cover. In the end I went with placing the reassembled Elf between two 1/4 inch polycarbonate panels separated with four nice aluminum spacers. I liked the overall look and the ease of construction. Also with all the sides remaining open, it allowing great ventilation.

|

Top end view of the finished Quest Elf I

On the back edge edge of the Elf was placed a 7 1/2 x 1 inch length of aluminium angle. Here was placed the coaxial power connector and a small switch used to turn off the speaker connection to the Elf's Q output.

The Elf's bottom view show the voltage regulator mounted on its heat sink, the supporting electrolytic capacitor, the 1 megahertz crystal and a high performance speaker assembly connected to the Elf's Q driver circuit. Note the addition of some 0.1uF decoupaging capacitors. The original Quest Elf I really was very light on decoupling capacitors sometimes leading to some strange behavior during operation.

Note also the addition of a short red wire used to fix the one area of foil damaged during the deconstruction.

|

|

| Bottom view of the finished Quest Elf I |

|

|

|

|